Swiss CNC Machining Services

Precision custom CNC Swiss screw machined parts at low costs

Swiss CNC Machining Services

Precision Swiss CNC machining services are our specialty at TIANYIDA. We are proficient in Swiss-type machining with the use of the most advanced technologies and equipment, allowing us to produce high-quality precision-turned parts. We can offer you suitable cost-effective solutions no matter how complex your desired microcomponent is.

What is Swiss CNC Machining

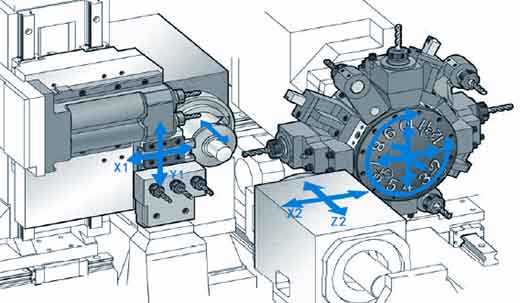

Swiss CNC machining is a specialized process to machine small, high precision turned parts. A Swiss CNC machine, also referred to as a Swiss automatic lathe, Swiss screw machine, or Swiss-type lathe, was originally designed for the Swiss watchmaking industry. Over the years, the Swiss-style turning machine has been refined to be widely used in various industries for high-volume, high-precision manufacturing – and for good reason.

A Swiss-style lathe is a type of machine that cuts bar stock fed through a guide bushing while the tools keep stationary. The collet is recessed behind the guide bushing so that the bar stock held in it will have better support and will not directly be exposed to the lathe bed and the tooling, so the machine can process the material rapidly and tightly. Also, it plays a great role in decreasing tool deflection and vibration while increasing parts accuracy since the cutting tool can work nearer to the bushing.

The Key Benefits of Swiss CNC Machining

The good performance of Swiss CNC machining greatly benefits from the guide bushing and the geometry and mechanics that take place in the tool zone.

Swiss CNC Machining Parts Gallery